Member Company: Armstrong Flow Control – Melbourne

Armstrong Flow Control – Melbourne

Website: https://armstrongflow.com.au/

Armstrong Flow Control – Melbourne

Website: https://armstrongflow.com.au/

ANCA is a privately-owned Australian business that manufactures CNC tool and cutter grinders, motion controls and sheet metal solutions. While the global headquarters remain located in Melbourne, Australia, due to the niche markets we service ANCA exports 99% of our products with 2,500 customers in over 45 countries and we have offices in the UK, Germany, China, Thailand, India, Japan, Brazil and the USA as well as a comprehensive network of representatives and agents worldwide.

Since 1974, ANCA has gained worldwide recognition in the industry as a leader in the technology. Several industry firsts include designing and manufacturing an Australian CNC, introducing a probe for digitising tools in a CNC tool and cutter grinder, introducing MPG Feed for safe program debugging and testing, and introducing full and true 3D simulation of the grinding process through our CIM3D software (patented in Australia and USA).

Our engineering excellence and export achievements have been honoured with more than 25 industry and business awards including the 2018 Australian Financial Review Most Innovative Companies and the Governor of Victoria Export Awards – Manufacturing Award. In 2016 ANCA was inducted into the Australian Exporter of the Year Hall of Fame after winning the top accolade three times in 2015, 2012 and 1995.

At ANCA we provide a complete solution to our customers, designing and manufacturing almost all our technology in-house. We partner with our customers to create bespoke solutions and invest almost 10% of our annual turnover on research and development so our customers always have access to market-leading technology. A major factor in ANCA’s success is that we were “born global” which means offering global support is in our DNA. Our ambition is that for our customers, no matter where they are located is that we appear just as responsive as a local company.

Read more at www.anca.com

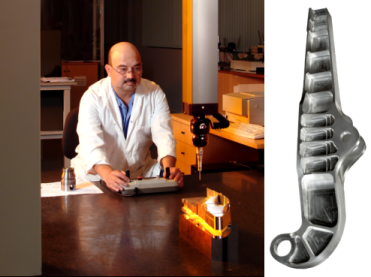

Melbourne’s Professional Engineering Manufacturers

We are one of Australia’s most innovative and experienced engineering firms.

Andrew Engineering is widely recognised as a leading producer to the rail, defence, automotive and mining industries. We are able to provide custom, purpose-built solutions to industries throughout the country, as well as help in international projects.

A complex industry, we continue to innovate through constant product testing, regular collaboration with partners and customised, tailored equipment. We ensure each project complies with regulations and standards, and maintain a high level of customer satisfaction.

Read more at http://www.andeng.com.au/

Dimac Tooling is Australia and New Zealand’s leading supplier of accessories and workholding solutions for CNC milling and CNC turning machine tools.

Dimac is motivated to continually finding more effective, safe and productive ways to hold and machine workpieces. We manufacture Soft Jaws, Hard Jaws and Custom Jaws in our own CNC equipped machine shop and this capability, coupled with over 30 years experience doing so, ensures we provide the right workholding solution for you.

Read more about Dimac on their website www.dimac.com.au .

Lovitt Technologies Australia Pty Ltd owned and operated by Mike Ramsay

Lovitt Technologies Australia (LTA) was founded in 1954 as George Lovitt Manufacturing Pty Ltd. It commenced operation in the manufacture of cutting tools and components for the automotive industry.

Over the past 50 years, LTA has evolved with the demands of its customers, and embraced contemporary precision engineering technologies to offer enhanced capabilities in new markets.

Today, the company is a provider of precision machined tools, components, parts and assemblies to customer design and specification particularly within the aerospace and defence industries.

We recognise that customers need more than parts formed from metal, and offer the ancillary services of assembly, finishing and supply chain solutions to ensure customers gain maximum value from engaging Lovitts.

Australian Defence Manufacturer Wins Global Contract

Sutton Tools is a proud family business with 90 years of experience in tool making.

Jim Sutton and the late Bill Sutton, both Vernier members, built upon the business their father established and have positioned the company so that the Sutton brand is recognisable internationally. Now Peter Sutton, Chief Manufacture Officer, brings the next generation to Vernier. Phillip Xuereb, also a member Vernier, is Chief Engineering Executive at Sutton.

Sutton Tools has a vibrant and successful apprentice programme and currently works with local and state governments to encourage youth into manufacturing.

Watch youtube video of Sutton Tools on ABC Program

Balcombe Engineering Pty Ltd has been the leading Australian specialist manufacturer in the flange industry for over 50 years servicing a diverse range of customers for flanges, spectacle blinds and tubeplates / tubesheets, in the Petrochemical, General Industrial, and Food industries.

The Melbourne facility is located in Hallam and houses Australias largest range of flanges and valves as well as a comprehensive in house manufacturing facility. Large stocks, and inhouse manufacturing, enables Balcome to provide any required flange, spectacle blind, or valve in a few hours if its in stock and between next day and 2 weeks if it has to be custom manufactured.

Ronson Gears are one of Australia’s leading gear manufacturers. We utilise the very latest in CNC gear profile grinding, CNC gear cutting and CNC rack milling technology and an Australian first in CNC gear metrology from Germany. All of which give our customers products of the highest quality.

The company manufactures spur gears, helical gears, bevel gears, gear racks, worms and worm wheels and many other power transmission related products used worldwide. From medium to low volume precision ground gears for the rail, mining and agriculture industries to high volume automotive applications. Other industries serviced are the aviation, aerospace and construction industries. Ronson Gears are internationally competitive.

18 Teton Crt, Highett, VIC 3190

Tel: +61 3 9555 9822 Fax: +61 3 9555 7480

Website: www.ronsongears.com.au

Email: enquiries@ronsongears.com.au